Effective communication within pharmaceutical plants and clean rooms is crucial for maintaining safety, compliance, and operational efficiency. The J&R Pharmaceutical Plants & Clean Rooms Intercom System offers a tailored communication solution that ensures clarity, reliability, and security across these highly regulated environments. This article explores how the advanced features of this intercom system support seamless communication while upholding strict environmental and safety standards Nuclear Power Plants Secure Communication System.

Enhancing Safety Through Reliable Communication

Pharmaceutical plants and clean rooms demand stringent control over contamination risks and operational hazards. The J&R Pharmaceutical Plants & Clean Rooms Intercom System is designed to provide crystal-clear communication channels that help mitigate risks by enabling instant contact among personnel. In these critical settings, every second counts, and this intercom system allows quick coordination without compromising the controlled atmosphere.

The system’s durability and compatibility with clean room protocols make it a valuable asset. It allows workers to maintain secure communication without physical movement that could breach sterile zones. The ability to communicate instantly can prevent accidents, reduce downtime, and promote a culture of safety that aligns perfectly with regulatory requirements.

Seamless Integration with Controlled Environment Standards

Integration with existing infrastructure is a fundamental feature of the J&R Pharmaceutical Plants & Clean Rooms Intercom System. Designed with flexibility in mind, it adapts effortlessly to the unique layouts and stringent requirements typical of pharmaceutical manufacturing and clean room operations.

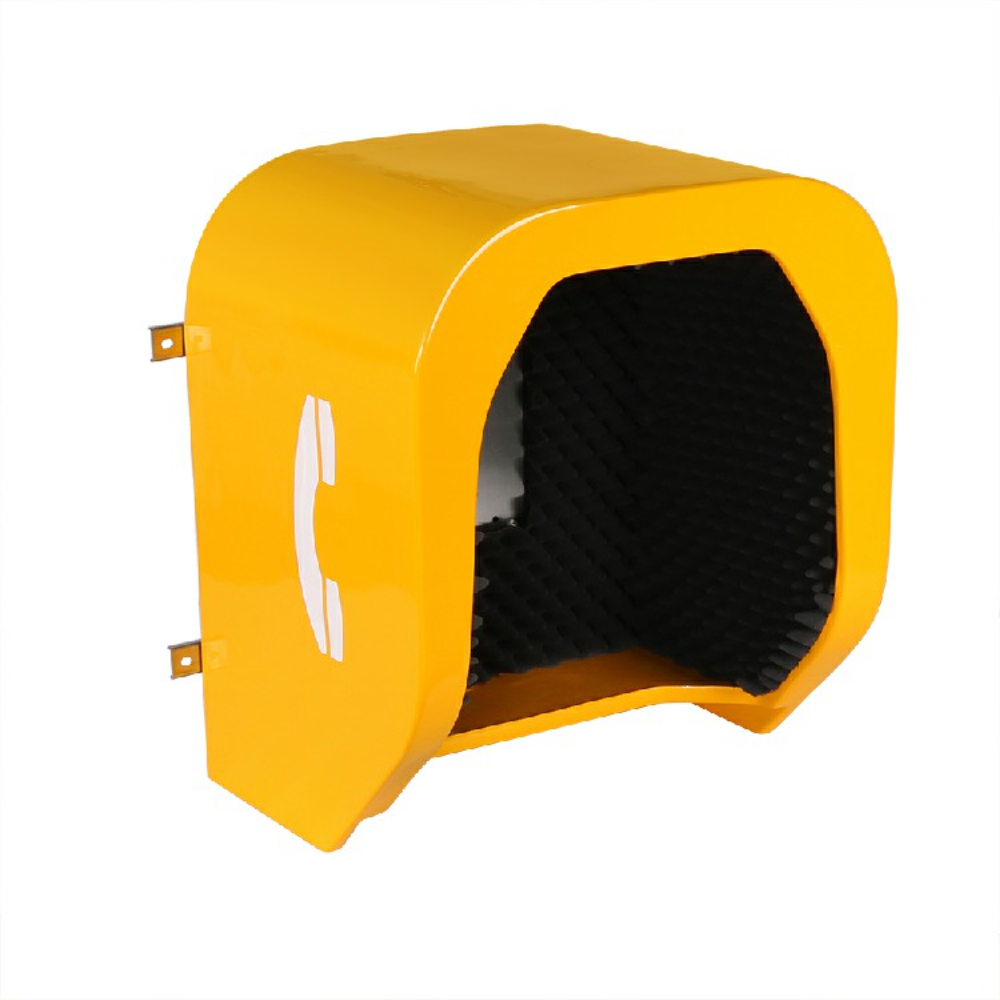

This intercom solution supports noise reduction and clear voice transmission, essential in environments where precision and attention to detail are paramount. By facilitating uninterrupted communication, it supports compliance with hygiene and operational protocols. The system’s design ensures that communication devices can be easily cleaned and maintained without compromising functionality or sterile conditions.

Supporting Operational Efficiency and Compliance

The J&R Pharmaceutical Plants & Clean Rooms Intercom System significantly boosts productivity by streamlining communication workflows. Efficient communication contributes to faster decision-making, quicker response times, and better coordination among teams managing sensitive pharmaceutical processes.

In a setting where contamination control and strict procedural adherence are mandatory, this system allows staff to communicate securely without compromising cleanliness standards. It supports ongoing monitoring and supervision, providing a direct line for reporting issues or emergencies immediately. This capability ensures that pharmaceutical plants maintain high compliance levels while fostering smooth operational flow.

Technology Empowering Communication Security

While the pharmaceutical industry places utmost importance on safety and hygiene, communication security cannot be overlooked. The J&R Pharmaceutical Plants & Clean Rooms Intercom System integrates advanced encryption and access control features, safeguarding sensitive information shared across the network.

This system’s robust security protocols align with industry standards for data protection, making it ideal for facilities handling confidential pharmaceutical formulations and processes. In this regard, it shares a similar focus with the Nuclear Power Plants Secure Communication System, which prioritizes secure and reliable communication in high-risk environments.

The parallels between these two systems emphasize the necessity of secure communication channels where operational integrity and safety are paramount. Both systems serve as critical components of the safety infrastructure in their respective sectors, ensuring uninterrupted and protected communication pathways.

Reliability Under Challenging Conditions

Pharmaceutical plants and clean rooms often operate in controlled but challenging conditions, including strict temperature, humidity, and cleanliness controls. The J&R Pharmaceutical Plants & Clean Rooms Intercom System is engineered to perform reliably under such conditions, providing consistent communication without degradation.

This reliability ensures that workers can maintain constant contact without the fear of communication failures, which could jeopardize product quality or safety. The system’s rugged design and adherence to industry standards make it suitable for continuous operation in sterile and tightly regulated environments.

Bridging Communication in Complex Facilities

Modern pharmaceutical manufacturing involves complex layouts with multiple clean room zones, laboratories, and processing areas. The J&R Pharmaceutical Plants & Clean Rooms Intercom System is designed to bridge these spaces seamlessly, offering clear communication channels that unify operations across the facility.

This interconnectedness supports better management of personnel and resources, enabling teams to react swiftly to operational demands or emergencies. In a similar vein, the Nuclear Power Plants Secure Communication System also addresses the need for seamless communication across sprawling, high-security installations, highlighting how vital well-designed communication systems are across industries with strict operational controls.

Conclusion: Elevating Controlled Environment Communication

The J&R Pharmaceutical Plants & Clean Rooms Intercom System stands as a critical tool for pharmaceutical facilities aiming to maintain stringent control and safety standards. Its ability to provide secure, clear, and reliable communication enhances operational safety and efficiency, supporting compliance with rigorous regulatory demands.

Drawing a parallel to the Nuclear Power Plants Secure Communication System reveals a shared commitment to secure and dependable communication in sensitive environments. Both systems embody the importance of technology-driven solutions that protect personnel, safeguard sensitive operations, and ensure continuous, effective communication in their respective domains.

By choosing the J&R Pharmaceutical Plants & Clean Rooms Intercom System, pharmaceutical facilities invest in a communication network tailored for controlled environments, where safety and precision are paramount and instant connectivity is essential.